Matics Webinar: Increase Profitability With a Real-time Production Floor Management System

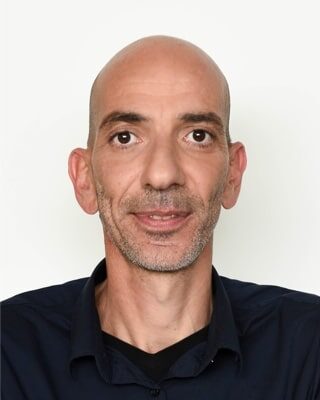

The modern manufacturing landscape is highly competitive and is undergoing rapid change as manufacturers implement the latest solutions. Our most recent Matics webinar draws the connection between the advantages provided by a real-time production floor management system and the impact it has on a manufacturer’s profitability. The webinar is hosted by Business Development Manager at Matics, Elie Slama, who is

Last Modified: March 14, 2024