How to Build a Dynamic Manufacturing Dashboard

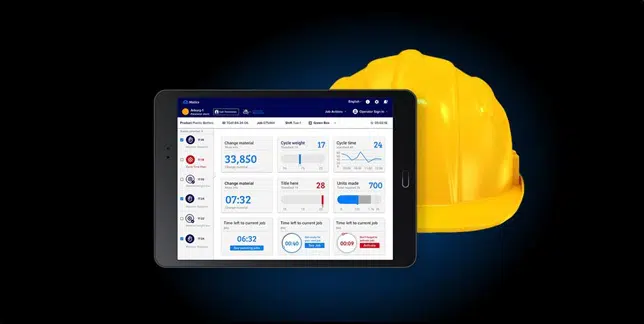

Because of its critical role in disseminating information amongst the team, the dashboard is perhaps the most important element of shop floor control software. A dynamic dashboard allows supervisors and workers alike to track production inside a factory using shop floor control software. Set up correctly, dynamic KPI dashboards can bring order to factory production and significantly increase both output

Last Modified: July 20, 2023